| Product Code | Density | Thickness | Width | Conductivity | Packing | PKG/40'HQ | |

|---|---|---|---|---|---|---|---|

(kg/m3) | (mm) | (mm) | (W/m•K) | (pcs/PKG) | |||

| TR HVPL 4825 | 48 | 25 | 600 | 0.035 | 1 | Loading Qty, | ATION |

| TR HVPL 4830 | 48 | 30 | 600 | 0.035 | 1 | Please consult | |

| TR HVPL 4840 | 48 | 40 | 600 | 0.035 | 1 | ||

| TR HVPL 4850 | 48 | 50 | 600 | 0.035 | 1 | ||

| TR HVPL 6425 | 64 | 25 | 600 | 0.034 | 1 | ||

| TR HVPL 6430 | 64 | 30 | 600 | 0.034 | 1 | ||

| TR HVPL 6440 | 64 | 40 | 600 | 0.034 | 1 | ||

| TR HVPL 6450 | 64 | 50 | 600 | 0.034 | 1 | ||

| TR HVPL 9625 | 96 | 25 | 1200 | 0.032 | 1 | ||

| TR HVPL 9630 | 96 | 30 | 1200 | 0.032 | 1 |

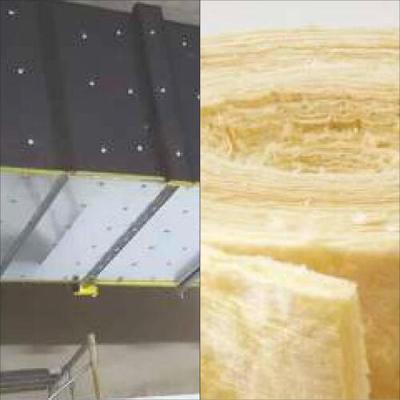

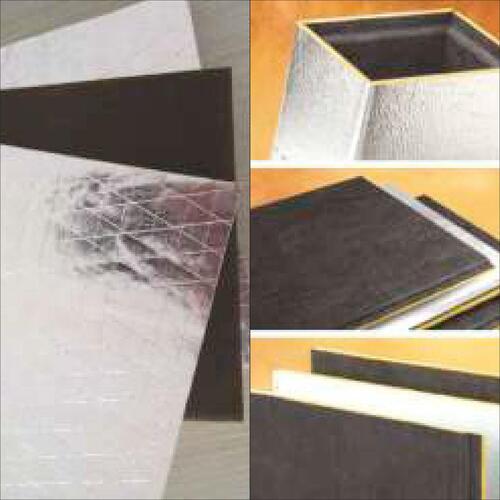

HVAC System Insulation Glass Wool Duct Panel

Application

- Use in the fabrication of HVAC systems, air diffusers and register boxes

- Used to fabricate ducts for commercial and residential construction

- Use in manufactured and modular housing duct system

Features And Benefits

- Excellent thermal and acoustic properties

- Long product life - will not readily age

- Excellent mechanical performance

- Less wasted energy