| TS EN 13501-1 (Reaction to Fire) | : B |

| TS EN 12667 (Thermal Conductivity X) | : 0.037 W/(m-K) |

Acoustic Spray - Tranquil ACSILO

Sound deadening Spray foam is an eco-friendly and sustainable solution made from recycled fibers and boron salts, utilizing advanced technology. This material offers outstanding acoustic and thermal insulation capabilities.

Applied in its fiber form, the cellulose wool is sprayed onto the desired surface, making it an ideal option for acoustic spray Ceiling treatments.

Sound deadening spray foam quickly gained global popularity due to its ecological benefits and sustainability. This innovative acoustic spray solution is now widely used for superior noise control and insulation.

Technical Specifications

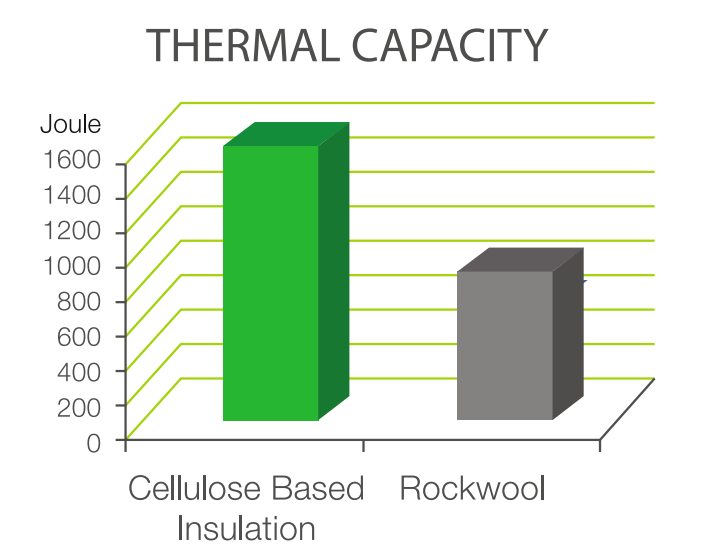

Thermal Volume is the amount of energy required to heat or cool one kilogram of material by one degree Celsius. The material will be more insulating if the value is high. Glasswool has a thermal capacity of 670 joules per kg, while rockwool has a capacity of 860 joules per kg. According to EN ISO 10456, the thermal capacity of cellulose-base insulation produts is close to 1600 joules per kg (A performance 2-2.5 times better that their substitutes).