Metal Building Wall Insulation Glass Wool Blanket

Product Information

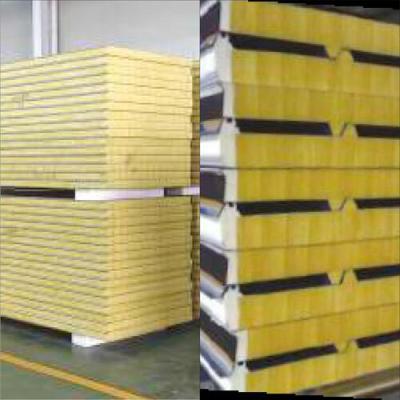

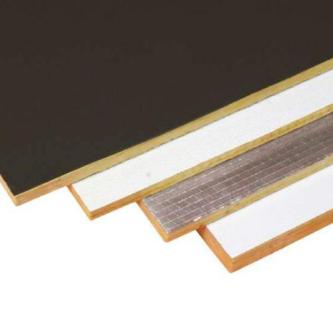

Tranquil APS metal building wall Insulation glass wool blanket is consisted of long, resilient fibers bonded together with a thermosetting resin to form a lightweight, flexible glass wool blanket. The blankets can be supplied with a factory applied foil vapor barrier (FSK, Vinyl, Foil, WMP, and Kraft Facing) accordingly to project designs or customer’s requirement

Features And Benefits

- Improve the energy efficiency of the building

- Reduce transmission of exterior sound to the interior of the building

- Absorb reverberating sounds within the building

- Provide thermal efficiency

- Keep the building warmer in winter and cooler in summer.

Application

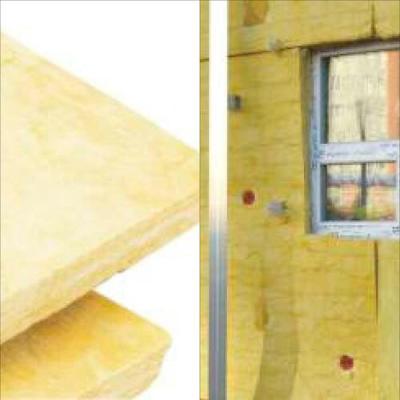

Metal Building Insulation glass wool blanket is designed for use under any wall system supported on purlins with either metal or fibrous claddings, to provide thermal control within the building. The blanket also be used as additional insulation to fill voids in walls and roofs of metal buildings Metal Building Insulation glass wool blanket is designed for use under any wall system supported on purlins with either metal or fibrous claddings, to provide thermal control within the building. The blanket also be used as additional insulation to fill voids in walls and roofs of metal buildings

Available Forms

Flexible Blanket and Roll

Available Size

Product Code | Density | Thickness | Width | Conductivity | R-Value | Packing | PKG/40'HQ |

| (kg/m3) | (mm) | (mm) | (W/m•K) | (m²•K/W) | pcs/PKG |

| TR BIR 1250 | 12 | 50 | 1200 | 0.039 | 1.2 | 1 | Loading Qty, | ATION |

| TR BIR 1275 | 12 | 75 | 1200 | 0.039 | 1.9 | 1 | Please consult |

| TR BIR 12100 | 12 | 100 | 1200 | 0.039 | 2.5 | 1 |

| TR BIR 12150 | 12 | 150 | 1200 | 0.039 | 3.8 | 1 |

| TR BIR 12200 | 12 | 200 | 1200 | 0.039 | 5 | 1 |

| TR BIR 1650 | 16 | 50 | 1200 | 0.038 | 1.3 | 1 |

| TR BIR 1675 | 16 | 75 | 1200 | 0.038 | 1.9 | 1 |

| TR BIR 16100 | 16 | 100 | 1200 | 0.038 | 2.6 | 1 |

| TR BIR 2450 | 24 | 50 | 1200 | 0.035 | 1.4 | 1 |

| TR BIR 2475 | 24 | 75 | 1200 | 0.035 | 2.1 | 1 |

| TR BIR 24100 | 24 | 100 | 1200 | 0.035 | 2.8 | 1 |

Physical Properties Of TR BIR 1650

| Tested Content | Tested Method | TestedValue |

| Density | ASTM C612 | 16kgs/m3 |

| Thickness | GB/T 17795-2008 | 50mm |

| Average diameter of fibers | GB/T 17795-2008 | 6.8μm |

| Coefficient of Heat Conductivity | EN12667 | 0.038W/m·K |

| Thermal Resistance | ASTM C653 | 1.30m²·K/W |

| Average NRC | EN ISO 354 | 1 |

| Maximum Service Temperature | ASTM C411 | 177°C |

| Corrosion Resistance | ASTM C665 | No Chemical Reaction |

| Mold Resistance | ASTM C665 | Mildew proof |

| Moisture Absorption | ASTM C1104 | Less 3% by weight |

| Humidity veneration Rate | ASTM E96 | Max 0.013g/24Hours·m² |

| Non-Combustibility | ASTM E84 | Flame Propagation: 25; Flame Diffus conductivity 50 |

Storage And Transport

Store insulation indoors. Store product under cover and in dry conditions. Handle with care, Products will be damaged if subject to sharp or heavyimpact.

Quality Management And Specification Compliance

ISO 9001: 2008, ISO 14001:2004 GB/T17795-2008, GB/T23932-2009, EN ISO 354, EN12667, ASTM C177, ASTM C653, ASTM C665 With CE Certificate according to standard EN 13162:2008

Fire Performance

Classified as Euroclass A1 to STN EN 13501-1: 2007, and GB/T5464-2010 , GB/T14402-2007.